EuroEnergest project

Energy testing of the SEAT automaker in Spain

1. Introducing the EUROENERGEST project

The EuroEnergest project is supported by the European Commission under the 7th Framework Programme, and it was started on 1st October 2011. The technical research centres, universities and private companies involved in the project have the aim to develop an intelligent energy management system (iEMS), and reduce min. 10% of the energy consumption of the automotive industry, mainly in the HVAC systems.

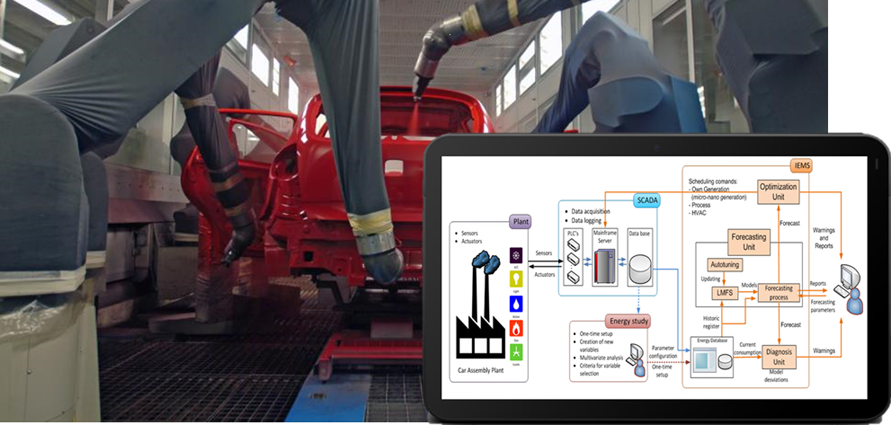

Long-term goal of the project is that the developed system can be used in other production plants in addition to the car manufacturing factories, making it possible the energy-efficient operation and energy-saving. Nowadays used EMS systems primarily “passive” monitoring systems, that produce periodic reports on energy efficiency, sent alarm signal for the user at the peak of the energy consumption, but EMS does not take autonomous actions for improvement of energy efficiency, and does not apply a dynamic simulation for the energy generation and energy consumption systems. The aim of the developed intelligent energy management system (Figure 1) is providing connection between industrial production, and energy production,- and consumption, applying dynamic simulation, giving forecast for the expected energy consumption, optimizing the needed energy consumption and production, and maximizing local and low-carbon energy sources (e.g. photovoltaics, CHP).

Figure 1. iEMS system is under development

Figure 1. iEMS system is under development

The participants of the Consortium involved in the project:

- SEAT car manufactory (Spain)

- Enertika Ltd (Coordinator of the Consortium, Spain)

- UPC, Universitat Politècnica de Catalunya (Technical University of Catalonia, Spain)

- VTT, Technical Research Centre of Finland

- Brunel University (United Kingdom)

- Comfort Consulting Kft. (Hungary)

A key part of this project is the enthusiastic involvement of one of Europe’s most important automobile manufacturers, SEAT, the member of VW group. This involvement gives EuroEnergest the opportunity to verify the developed system in a real world situation, in the car manufactory of SEAT. The factory is in Spain, in Martorell close to Barcelona. In the factory SEAT Ibiza, Altea, Leon, Exeo and AUDI Q3 type cars are made. In the past years an average of approximately 360,000 cars were made yearly in the Spanish factory, which means in every one and a half minutes a car was manufactured. The pressing and welding of the car body panels, the assembly and the painting of the complete car body, the installation of the engine, gearbox, brakes and other components and finally testing and quality controlling of the vehicle are made in the factory.

Comfort Consulting Ltd is the leader of the first work package, which contains the study of the car manufacturing process used nowadays, defining the energy demands, and elaborate the validating system for the software under development in the project.

2. The energy demand of the car manufacturing

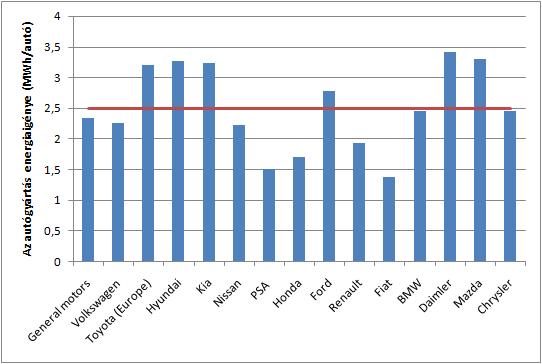

One part of the work of the EuroEnergest project is to study the car manufacturing process, to define the energy needs of the different process steps, and compare the energy consumption of the different car manufacturers. Worldwide vehicle production is more than 80 million, from which the European vehicle production is nearly 18 million, therefore the energy demand of the car manufacturing is very important, because an enormous amount of energy we are talking about. Accurate data were available for SEAT Martorell factory for several years back, while documents published by ACEA (European Automobile Manufacturers' Association) and the data of the publicly available annual reports were taken into account regarding the other manufacturers.

Figure 2 The energy demand of the car manufacturing

Figure 2 The energy demand of the car manufacturing

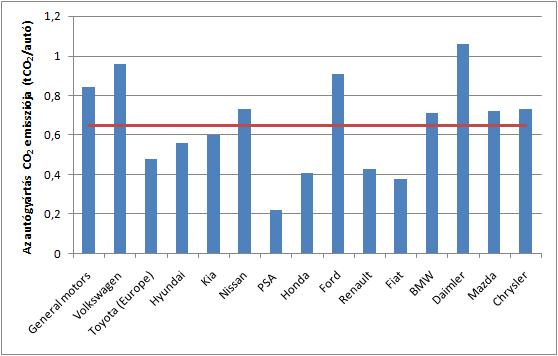

Figure 3 The CO2 emission of the car manufacturing

Figure 3 The CO2 emission of the car manufacturing

Based on our studies, the energy demand of the car manufacturing is from 1.39 to 3.42 MWh/car, the average is 2.5 MWh/car, while the CO2 emission is 0.65 t/car. If the energy need of the car manufacturing can be reduce with 10% in the near future, which means an average of 0.25 MWh/car energy saving, it results 100,000 MWh per year energy saving for a factory, which produces 400,000 pieces cars per year. The energy need of Martorell car manufactory is still below the average 2.5 MWh/car, but it is partly due to the mild weather, therefore the energy demand can be further reduced by more efficient use of the energy resources, and optimization of the energy generation and consumption.

3. The process of the car manufacturing

The basic steps of the car manufacturing are very similar between manufacturers, but differences can be observed in some technologies (such as painting) and automation. During the EuroEnergest project the car manufacturing process steps and its energy demands were studied. The four main steps in the car manufacturing are the pressing, bodywork, painting and final assembly, which together give 80-85% of the total energy consumption.

Figure 4 Car manufacturing in nowadays

Figure 4 Car manufacturing in nowadays

3.1 Pressing process

The automotive manufacturing process starts in the pressing workshop, where door panels, roof, bonnet, boot, etc. are pressed to form the basic structural parts of the automobile. The main energy consumers are the blanking machine, pressing machine, heating- and cooling system and air system. The pressing process has the lowest energy consumption among the four main process steps, it takes about 4% of the energy need of the whole car manufacturing process.

3.2 Bodywork process

In most of the car factories the bigger parts of the welding process are done by automated robots, in Martorell there are 1,518 robots in the body workshop. The main energy consumers are the welding and assembly robots, exhaust ventilation system from the welding area, and the air conditioning system. The energy consumption of the bodywork process is about 20% of the energy need of the whole car manufacturing process.

3.3 Painting process

From the body workshop the completed “body-in-white” vehicles are moved to the painting workshop, where the whole painting process of one vehicle body takes about 6-12 hours. The main energy consumers are the pre-treatment machines, painting robots, air handling units of process and comfort zones, heating and cooling systems. The energy consumption of the painting process has the biggest part of the energy need of the whole car manufacturing process, because it takes approximately 40% of the energy demand, based on the 2010-2012 years’ energy consumption of SEAT Martorell factory.

3.4 Final assembly process

After the body painting follows the installation of the various components in the car. The assembly is the least automated process and therefore it is the most labour intensive process. The energy need of the assembly process is close to the bodywork process, as it takes about 20% of the total energy demand.

4. The energy supply system of SEAT Martorell factory

Based on the energy need of the different process steps, the EuroEnergest project focuses on the biggest energy consumers, i.e. the body workshop and the painting workshop, therefore the iEMS system (under development) will optimize the energy consumers in these workshops, and the energy production system. The energy supply system in the Martorell factory are one combined cycle power plant with 36.5 MW thermal and 21.5 MW electrical performance, three pieces of gas boilers each with 33 MW thermal performance, and one solar PV system with 8 MW electrical power. The body workshop studied in the project is approximately 100,000 m2 and 1,800 people work here. The workshop 1 involved in the project has 36 pieces of air handling units, which supply a total of 2,400,000 m3/h air flow. The cooling demands are satisfied with 2x4.8 MW absorption chillers made by YORK, and with 6 pieces of water chillers (5.7 MW total cooling performance) made by Climaveneta. In workshop 5 (painting workshop) the air handling units of process areas supply 2,583,000 m3/h air flow, while the air change of the comfort areas made by 20 pieces of air handling units with a total of 882,000 m3/h air flow. The cooling demands of the painting workshop are satisfied with 4 pieces of YORK absorption chillers with a total of 10.7 MW cooling performance, and 6 pieces of water chillers (6.7 MW).

5. Summary, next steps

Reducing energy use in the industrial, manufacturing plants is becoming increasingly important in the future. The EuroEnergest project presents a possible solution for energy saving through energy use reduction of a car manufactory, where modelling of the energy generation and energy consumption systems are made with different modules. Based on the developed modules the energy generation systems will connect with energy sources, as electricity and natural gas, through an energy hub. Based on the energy prices, the production data and the weather forecast and through intensive use of artificial intelligence algorithms to apply a dynamic simulation to energy generation and energy consumption models, the iEMS is able to optimize the energy generation and consumption systems. Industrial users and companies can take advantage of the individual modules, each of which can be used independently or all together linked to an existing Supervisory and Control Software. The iEMS system can be used in any car manufactory and in other manufacturing plants.